While most people may not give them a second thought, these humble corrugated boxes play a vital role in the shipping and packaging industries. And at the heart of every corrugated box lies its flute – an essential component that provides strength, durability, and protection. In this article, we will delve into the different types of flutes used in corrugated boxes. We’ll explore their unique characteristics, advantages, and disadvantages.

So, whether you’re a business owner looking to ship products or want to expand your knowledge on this topic, read on to discover everything you need to know about the types of flutes in corrugated boxes!

What is a Flute?

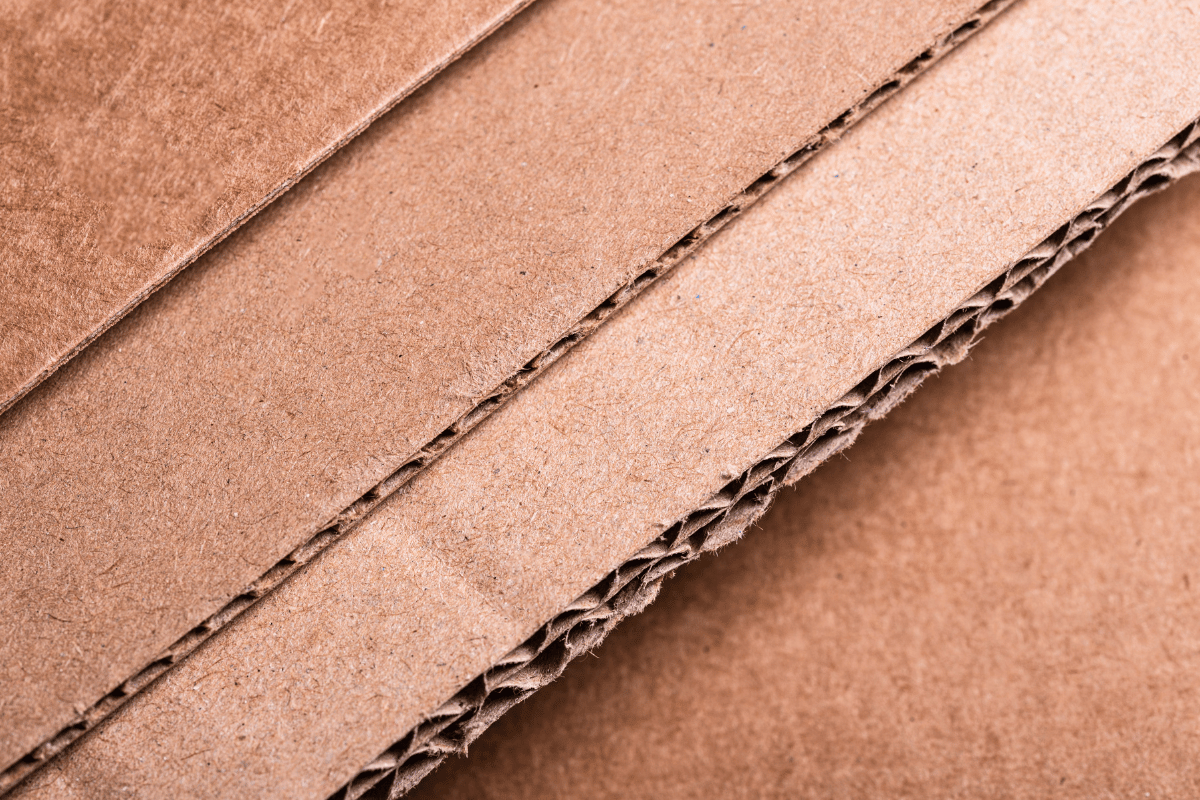

In the context of corrugated boxes, a flute refers to the wavy layer sandwiched between two flat liner boards. It adds strength and rigidity to the box structure while providing cushioning and protection for its contents. Think of it as the backbone of a corrugated box!

The flute consists of a type of paper known as a corrugating medium. This medium is usually crafted from recycled materials like old cardboard boxes or newspapers, promoting an environmentally friendly option.

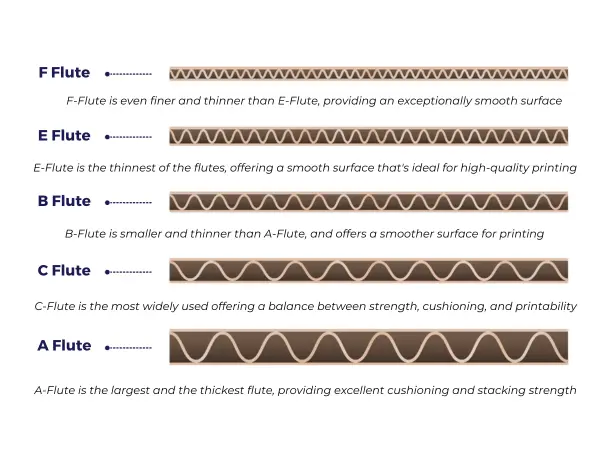

The most common styles of flutes include A, B, C, E, and F flutes. These letters represent the height and number of flutes per linear foot. Each type of flute has strengths and weaknesses regarding factors such as compression strength, stacking ability, puncture resistance, and printing quality.

Types Of Flutes In Corrugated Boxes: From A to F

When it comes to corrugated boxes, the type of flute used plays a crucial role in determining the strength and performance of the packaging. Flutes are the waves or ridges that run parallel to the box’s opening. They provide cushioning, rigidity, and structural support.

A flute is the thickest flute with extensive fluting, providing excellent stacking strength and compression resistance. It is commonly used for heavyweight products or when extra protection is required during shipping.

The B-flute has smaller fluting than the A-flute but offers better printability due to its flat surface. It provides good crush resistance as well as moderate stacking strength. B-fluted boxes are used for retail displays or small appliances.

The C-flute is a widely used flute due to its versatility. It balances thickness and good stacking strength while providing adequate cushioning properties. C-folded packages work well for shipping fragile items like glassware or electronics.

E-Flute consists of very fine fluting, which makes it ideal for printing high-quality graphics on packaging materials such as cosmetics or food products where presentation matters greatly.

F-Flutes have even finer fluting than E-Flutes, which makes them perfect for intricate die-cut designs and point-of-purchase (POP) displays requiring detailed graphics.

Pros and Cons Of Each Flute Type

When choosing the right type of flute for your corrugated boxes, it’s essential to consider the pros and cons of each option. Let’s take a closer look at some of the most common types of flutes and what sets them apart.

The B-Flute is one of the most popular choices due to its versatility. It offers excellent strength and cushioning properties, making it ideal for packaging delicate items such as glassware or electronics. However, its thicker profile may result in bulkier boxes and higher shipping costs.

C-Flute is your best bet for something thinner and reliable. It provides good stacking strength while maintaining a sleeker design. This makes it suitable for various applications, including retail packaging and displays. On the downside, C-flutes may not offer as much protection during rough handling or long-distance shipping.

E-Flute is the go-to choice for heavy-duty applications with maximum durability. With its thin yet dense structure, this flute offers exceptional crush resistance and superior printability. However, its reduced thickness can make it less resilient when facing impacts or compression forces.

There’s F-Flute, which stands out for its fine flute construction, creating an exceptionally smooth surface finish on printed boxes. Its compact design allows for efficient storage while still providing decent strength properties. Given its limited load-bearing capacity, F-flutes are not generally recommended for bulkier products.

So, How To Choose The Correct Type of Flute?

When it comes to choosing the right type of flute for your needs, there are a few factors that you should consider. First and foremost, think about the purpose of the corrugated box. Are you using it for shipping fragile items or heavy-duty products?

Next, consider the level of protection required. Each type of flute offers different levels of strength and durability. For example, a double-wall flute would be ideal if you need maximum protection. On the other hand, a single-wall flute might be suitable if you’re looking for a more cost-effective option without compromising on strength.

Additionally, take into account factors such as storage space and weight requirements. Some flutes may be thicker and bulkier than others, which can impact storage efficiency and transportation costs.

Don’t forget to consider your budget. Different types of flutes come with varying price points based on their composition and performance characteristics.

Still unsure? Don’t worry, we’re here to help you. Team up with a packaging company like Xetgo, with years of experience, and you can relax about these packaging worries. Just set up a chat with our team, and we’ll help you choose the best packaging for your products.