Introduction

If you’ve ever shipped or received a package, chances are you’ve encountered these sturdy boxes. In our last blog, we discussed what corrugated boxes are, the steps involved in making one, and their benefits. Today, we’re going to discuss the common types of corrugated boxes that are available in the market. So, if you’re a business owner looking for packaging solutions or simply curious about the world of boxes, we hope this guide will give you valuable insights into the diverse range of options at your disposal.

3 Types Of Corrugated Boxes

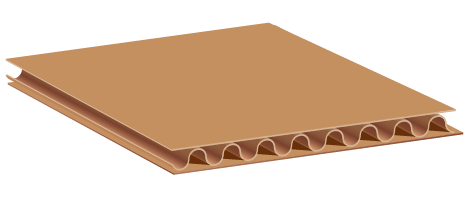

Single-Wall Corrugated Boxes

Single-wall corrugated boxes are a popular choice for packaging and shipping needs. These boxes have two layers of linerboard glued together with a single layer of fluted cardboard in between. They are lightweight yet sturdy, making them ideal for protecting goods during transit. The single-wall corrugated box is most commonly used for shipping items that don’t require extra protection, such as books, CDs, or DVDs.

One of the main advantages of single-wall corrugated boxes is their cost-effectiveness. Since they require less material to manufacture compared to double or triple-wall boxes, they tend to be more affordable. This makes them a great option for businesses that need budget-friendly packaging solutions without compromising on quality.

While single-wall corrugated boxes may not offer the same level of protection as double or triple-wall boxes, they still provide sufficient cushioning and structural integrity for many types of shipments. However, if you’re dealing with extremely delicate or valuable items, it may be worth considering stronger alternatives.

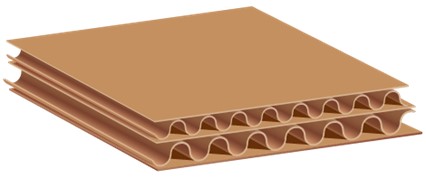

Double-Wall Corrugated Boxes

When it comes to packaging items that require extra protection, double-wall corrugated boxes are the way to go. These sturdy boxes are designed with two layers of fluted cardboard sandwiched between three sheets of linerboard, making them incredibly strong and durable.

The added layer of corrugation provides enhanced strength and rigidity, making these boxes ideal for shipping heavier and more fragile items. Whether you’re transporting delicate electronics or heavy machinery parts, double-wall corrugated boxes offer superior protection against impact and compression.

Not only do these boxes provide excellent structural support, but they also offer insulation properties. The air pockets created by the dual layers of corrugation act as a barrier against temperature fluctuations. This will help you in keeping your sensitive goods safe from heat or cold during transit.

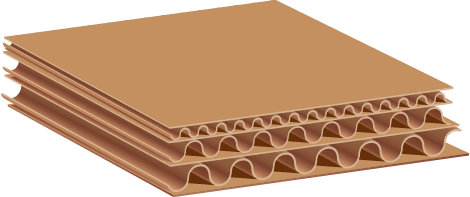

Triple-Wall Corrugated Boxes

Triple-wall corrugated boxes are the go-to solution for shipping items that require the highest level of protection. These boxes are made up of three layers of fluted cardboard sandwiched between four sheets of linerboard, giving them a maximum capacity of 100 lbs.

The extra layer in triple-wall corrugated boxes provides added strength and protection. This makes them ideal for transporting fragile or valuable goods. From industrial equipment to automotive parts, these boxes can handle it all!

Whether you need a box with reinforced corners or one that can stack securely on pallets, manufacturers can tailor-make triple-wall corrugated boxes for your exact requirements.

Conclusion

When selecting the right type of box for your business needs, it’s essential to consider a few factors. This includes such as product weight and fragility levels, along with shipping conditions and budgetary constraints. Consulting with a professional packaging supplier like Xetgo can help you make an informed decision based on your specific requirements. We can help you finalise the best-suited corrugated box type, so don’t hesitate to reach out to us.