Have you ever wondered how that carton of milk sitting in your fridge manages to stay deliciously creamy for weeks? Or how do those fruit juices maintain their vibrant flavours without any added preservatives? Well, get ready to dive into the fascinating world of aseptic food processing and its vast impact on the food industry!

In this post, we’ll take you on an exciting journey through the innovative techniques and technologies used to ensure freshness and safety in food products. So buckle up and join us as we unveil the mysteries of aseptic packaging in the food industry.

What Is Aseptic Food Processing?

Aseptic packaging is a process of packaging food products in a sterile environment so that the products do not need to be refrigerated or frozen. This type of packaging keeps food fresh and safe for consumption for long periods of time without the use of preservatives. Aseptic packaging is often used in the food industry, mainly for dairy products, juices, soups, sauces, and baby food.

Aseptic packaging is a process that involves packing food items in sterile containers to prevent spoilage and contamination. Manufacturers often use this type of packaging for shelf-stable products like milk or juices. Manufacturers can also utilize aseptic packaging for perishable items like meats or cheeses.

The main benefit of aseptic packaging is that it helps to extend the shelf life of food products. Aseptic packaging can keep food fresh for months or even years, depending on the product. This type of packaging also protects against bacteria and other contaminants. Aseptic packaging is, therefore, an important tool in ensuring the safety of food products.

How Does Aseptic Food Processing Work?

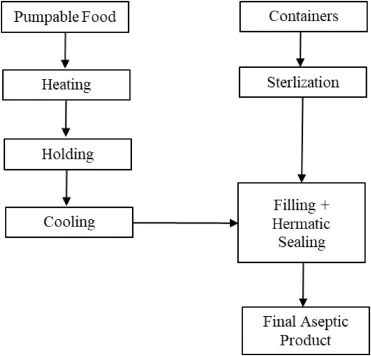

Aseptic food processing is a process that uses sterile equipment and conditions to package food products in a way that prevents them from coming into contact with microorganisms. It aims to maintain food freshness and ensure its safety for consumption.

It first begins with sterilizing the packaging materials. Achieving this involves using heat, radiation, or chemicals. Afterwards, the food product goes into sterilized packaging. In sterile conditions, operators seal the packaging to prevent contaminants from entering.

Furthermore, it allows for extended storage without the need for refrigeration or other preservation methods. Aseptic packaging protects food from bacteria, fungi, and other microorganisms that can cause spoilage or illness.

Conclusion

Aseptic packaging is an essential process in ensuring food safety and freshness. It sterilizing the packaging materials, controlling temperatures during processing, and keeping oxygen levels to a minimum, it helps preserve the quality of foods and beverages that are sensitive to environmental contaminants. With its ability to protect products from spoilage while maintaining their nutritional value for longer periods of time, it is no wonder that this important technology continues to gain popularity with consumers across the globe.